A815 WP S31803 duplex steel Lap Joint Stub Ends,ASTM A815 WPS UNS S 32205 Stub End Pipe fittings

We are a Duplex stainless steel A815 UNS S31803 stub end,A815 WPX S31803 duplex steel Lap Joint Stub Ends, ASTM A815 WPS UNS S 32205 Stub ends Pipe Fitting manufacturer,

ANSI/ASME B16.9 Buttweld Stub End Specification – Long Stub End, Short Stub End, Lap Joint Stub End

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 |

| Sizes | 1/2″NB TO 36 “NB IN |

| Types | Long Stub Ends, Pipe Stub Ends, Butt weld Long Stub Ends, Lap Joint Stub End. |

| Wall Thickness | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Production Grades | Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low temperature Steel, Carbon Steel, Cupro Nickel |

Manufacturing Standards of Buttweld Stub End, Lap Joint Stub End, Buttweld Long Stub End

| ASME: | ANSI B16.9, ANSI B16.28, MSS-SP-43 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

Stub Ends for Flanged Joints

A stud end and a lap joint flange can be used together as an alternative way to make a flanged connection than welding neck flanges.

The two devices to be combined, in this case, are:

- The stub end, which is essentially a piece of pipe, with one end flared outwards and the other prepared to be welded to a pipe of the same bore size (NPS = nominal pipe size), material and wall thickness. The most widely used fabrication tool for stub ends is the flaring machine, which is able to flare the end of the pipe and then cuts it to length.

- A Lap Joint Flange, which is used to actually bolt the two lengths of pipe together.

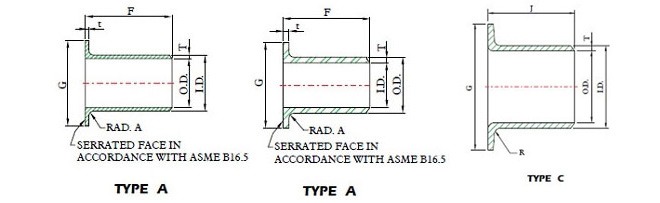

Stub ends are available in three different types, named “Type A”, “Type B” and “Type C”:

- The first type (A) is manufactured and machined to match standard lap joint backing flange (the two products have to be used in combination). The mating surfaces have an identical profile to permit a smooth loading of the flare face

- Stub ends type B are have to be used with standard slip-on flanges

- Type C stub ends can be used either with lap joint or slip-on flanges and are manufactured from pipes

SHORT/LONG PATTERN STUB ENDS (ASA/MSS)

Stub ends are available in two different patterns:

- the short pattern, called MSS-A stub ends

- the long pattern, called ASA-A stub ends (or ANSI length stub end)

Stub end material available in

| SPECIAL ALLOY | Inconel 600, Inconel 625, Inconel 718, Inconel X750, Incoloy 800, |

| Incoloy 800H, Incoloy 825, Hastelloy C276, Monel 400, Monel K500 | |

| WPS 31254 S32750, UNS S32760 | |

| STAINLESS STEEL | ASTM A403 WP304/304L, WP316/316L, WP321, WP347, WPS 31254 |

| Duplex& super duplex stainless steel | ASTM A 815 UNS S31803, UNS S32750, UNS S32760 |

We can produce high quality stainless steel elbow

Duplex stainless steel ASTM A815 WPS S31803 Pipe fittings elbow

ASTM A815 UNS S31803 Tee

ASTM A815 UNS S31803 Reducer

ASTM A815 UNS S31803 Stub end

We can produce high quality duplex stainless steel pipe fittings,Duplex stainless steel

A815 UNS S31803/1.4462 Chemical Composition

| Chemical Element | % Present |

|---|---|

| Carbon (C) | 0.0 – 0.03 |

| Chromium (Cr) | 21.00 – 23.00 |

| Manganese (Mn) | 2.00 max |

| Silicon (Si) | 1.00 max |

| Phosphorous (P) | 0.0 – 0.03 |

| Sulphur (S) | 0.0 – 0.02 |

| Nickel (Ni) | 4.50 – 6.50 |

| Nitrogen (N) | 0.08 – 0.20 |

| Molybdenum (Mo) | 2.50 – 3.50 |

| Iron (Fe) | Balance |

ASTM A815 / A815M – 18

Standard Specification for Wrought Ferritic, Ferritic/Austenitic, and Martensitic Stainless Steel Piping Fittings

This specification covers two general classes,

WP and CR, of wrought ferritic, ferritic/austenitic, and martensitic stainless steel fittings of seamless and welded construction. Class WP fittings are subdivided into four subclasses: Classes WP-S, WP-W, WP-WX, and WP-WU.

The material for fittings shall consist of forgings, bars, plates, or seamless or welded tubular products. The steel shall be melted by electric furnace, vacuum furnace, or electric furnace followed by vacuum or electroslag-consumable remelting. Forging or shaping operations shall be performed by hammering, pressing, piercing, extruding, upsetting, rolling, bending, fusion welding, machining or by combination of two or more of these operations. The materials shall undergo heat treatment and shall follow the required cooling process and tempering temperature. Chemical and product analyses shall be performed and shall conform to the required chemical composition in carbon, manganese, phosphorus, silicon, sulfur, nickel, chromium, molybdenum, copper, nitrogen, and titanium. The mechanical properties of the fitting material shall conform to the required values in yield strength, tensile strength, elongation, and hardness.

Duplex stainless steel A815 UNS S31803 are extremely corrosion resistant, work hardenable alloys. Their microstructures consist of a mixture of austenite and ferrite phases. As a result, duplex stainless steels display properties characteristic of both austenitic and ferritic stainless steels. This combination of properties can mean some compromise when compared with pure austenitic and pure ferritic grades.

Duplex stainless steels A815 UNS S31803 are in most cases, tougher than ferritic stainless steels. Strengths of duplex stainless steels can in some cases be double that for austenitic stainless steels.

Whilst duplex stainless steels are considered resistant to stress corrosion cracking, they are not as resistant to this form of attack as ferritic stainless steels. However, the corrosion resistance of the least resistant duplex stainless steels is greater than that for the most commonly used grades of stainless steels, i.e. 304 and 316.

Please make sure you have clearly marked the size,material grade and quantity for example.

PIPE FITTINGS-ELB 90 LR BW 2 SCH 80S ASTM A815 WPS UNS S 32205 SMLS (PIPE FITTINGS) 3 Ea

CON RED BW 2INCH X 1 1/4 INCH SCH 80/80 UNS-S31803 SMLS 5 Ea