Third party Inspection

QUALITY CONTROL

At C&N, All products are subject to strict in-process inspection at each stage of the production process, from starting material handling to finished product shipping. They are visually examined for conformity to the specifications and checked and tested in accordance with applicable ASTM, ASME, MSS, DIN, EN, and JIS codes and standards. Upon request, officially certified test agents can be called in to witness the inspection procedures

Material Receiving Inspections

Material inspections are carried out as follows.

1. Dimensional Inspection

Dimensions are checked at each end of the purchased material.

2. Visual Inspection

Surface check to ensure that material is correct and suitable for production of products.

3. Collating

Tests are done to ensure that the chemical composition and tensile properties of the described items are exactly as shown in the material certificates.

In-process Inspections

our products are manufactured from carefully selected materials of the finest metallurgical quality on well-controlled jigs, tools and molds. In order to ensure that all products meet quality specifications, the following in-process inspections are performed.

-Visual Inspection

-Dimensional Inspection

-Shape Inspection

-Hardness Test

-Temperature Check

-Processing Conditions Check

-Material Identification (marking)

-Other Inspections

Final Inspections

Our products are subject to the following final inspections before they are packed and delivered.

- Visual Inspection

Both internal and external surfaces are checked to confirm they are smooth and do not bear any harmful defects. - Dimensional Inspection

Done to ensure that all products are in conformity with dimensional tolerances of relevant Codes and standards. - Special Inspection

Non-destructive examinations and mechanical tests are performed as per customer’s Request.

4. Certification

inspection certificates are issued in accordance with DIN 50049/EN10204 unless otherwise requested by customers.

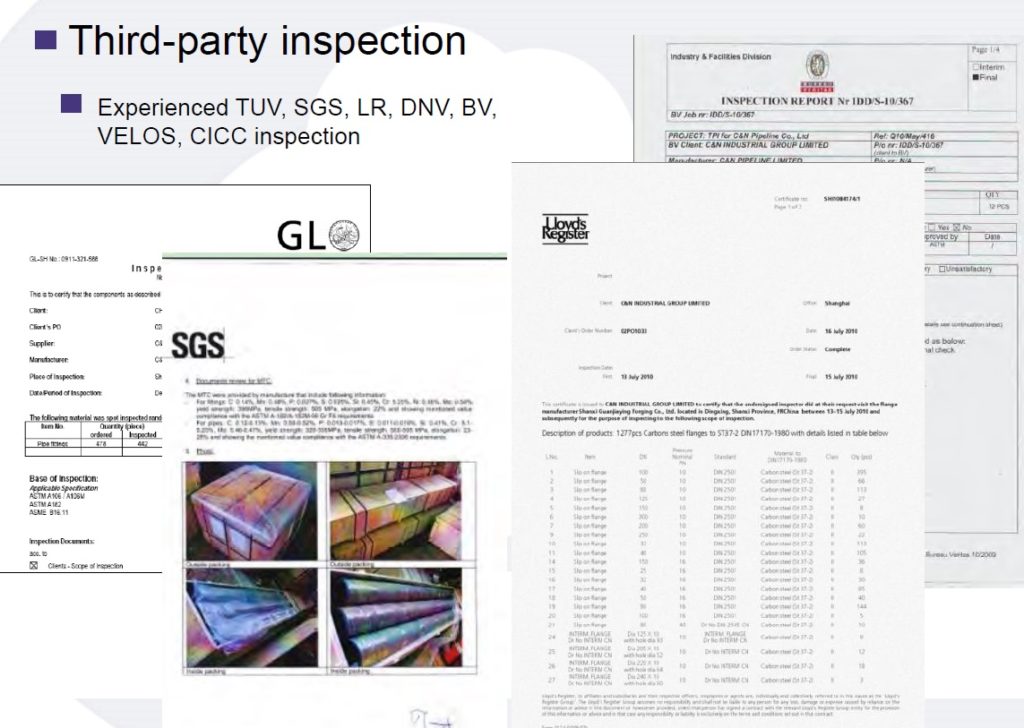

Third-party Inspections

our products subject to this inspection are made from starting materials stipulated by the regulations of the inspection body, e.g. BV, LR, DNV, SGS, etc. The staring materials and finished products are inspected for appearance, dimensions, and conformity to designated codes and specifications. The inspection body witnesses and certifies the inspections and issues certificates or report of findings to customers.

!

!